Leads the way in avoiding counterfeit and recycled electronic components.

IECQ Counterfeit avoidance programme

The IECQ Counterfeit avoidance programme (IECQ CAP), based on the IECQ Approved process scheme, provides means for obtaining certification and international recognition that an organization has an operational counterfeit avoidance plan and management system in place.

Original equipment manufacturers (OEMs) and their supply chain, including, for example, assembly service providers and component distributors, can use IECQ CAP to develop and implement the systems required to ensure that the introduction of counterfeit components into their production processes is avoided.

The organization’s counterfeit avoidance management plan (CAMP) is the master document describing the processes and process-control methods relevant to the range of activities and/or technical services for which the organization is seeking IECQ CAP certification.

Organizations that hold IECQ CAP certification demonstrate to the international marketplace that their organization and facilities comply with the requirements of the IECQ System for counterfeit avoidance.

Counterfeit avoidance management plans are based on the specific IECQ CAP requirements and international standards/specifications like:

IECQ OD 3702

Anti-counterfeit traceability audit for any industry segment

AS 6496

Franchised distributor plans

AS 6174

Counterfeit material: Detection, mitigation and disposition

IEC 62668-1

Avionics OEM anti-counterfeit plans

AS 5553

OEM anti-counterfeit plans

AS 6081

Non-franchised distributor plans

Understanding the challenge

"The 'Ticking Time Bomb' of Counterfeit Electronic Parts" industryweek.com

Counterfeit components

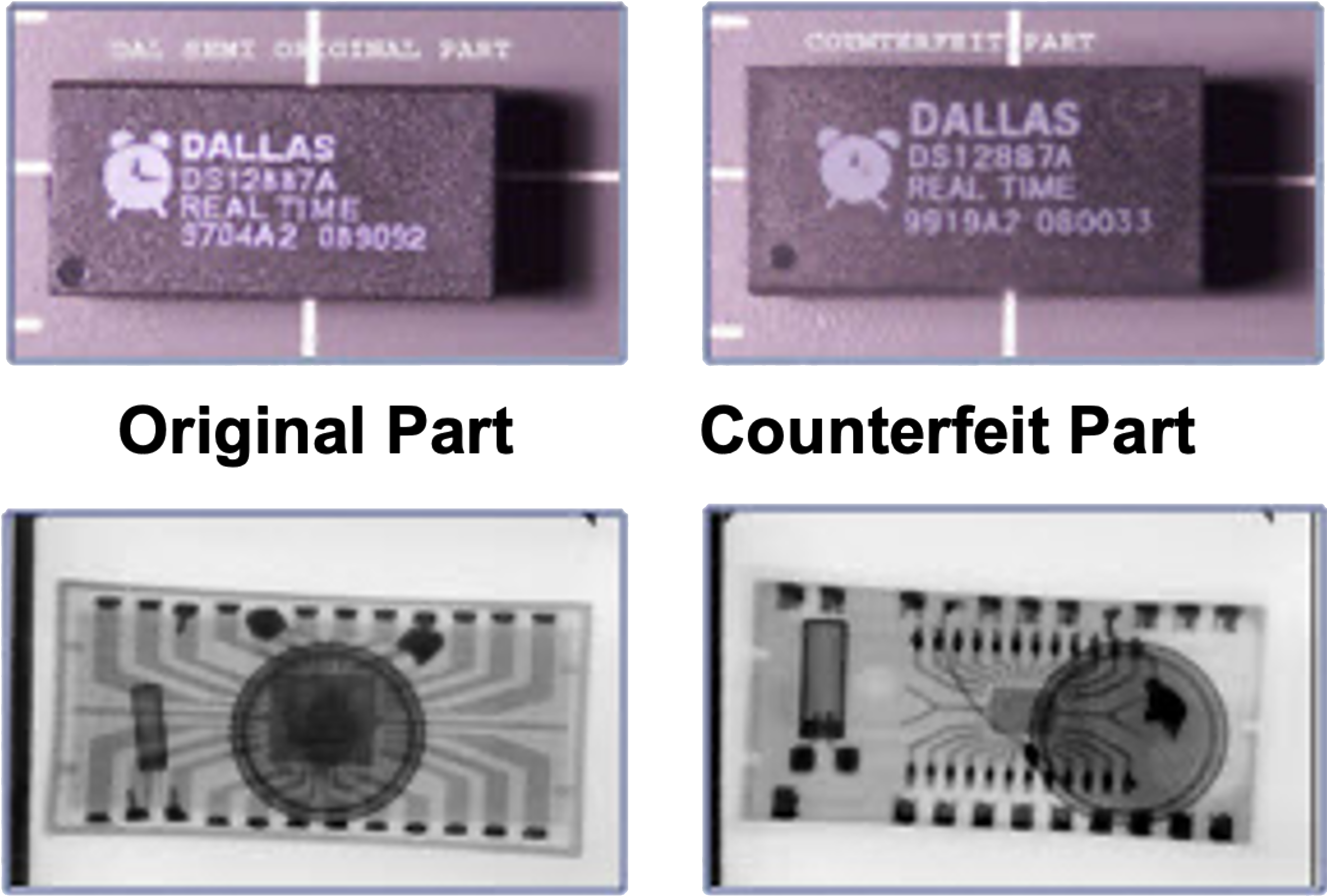

Counterfeit components

Over the past few decades, a significant number of counterfeit electronic parts have entered the supply chain. These components pose performance, reliability and safety risks.

Counterfeit electronic components often use cheap raw materials, are assembled poorly and lack testing and dye qualification by the original component manufacturer (OCM) or their service providers.

Situation & consequences

Counterfeit components are increasing, Can be:

- From manufactured from cheap substandard materials

- Incorrect dimensions, critical values & functionality

Can cause

- Safety risks

- Reliable risks

- Performance risks

- Environmental risks

- Production blockages

- Loss of sales contracts

External visual inspection cannot always easily find counterfeits.

Users need to know their supply chain to avoid counterfeits.

Fraudulent recycled components

Fraudulent recycled components

Over the past few decades, along with counterfeited components entering the supply chain, recycled components are also on the increase as older components become obsolete.

Recycled components are parts that have been removed from discarded devices, cleaned and re-labelled, and then presented to the market as new components.

Depending on their application, recycled electrotechnical components can be very dangerous and can create numerous risks, owing to the uncontrolled processes in which parts are removed, cleaned, and remarking, leading to high risks of damaging these components.

Situation & consequences

Fraudulent recycling is on the increase as older components become obsolete.

Reliability & performance risks

- Uncontrolled processes damage the components

- Useful life will have been used

- Usability impacts the original equipment manufacturer's (OEM) products' mean time before failure (MTBF) as will have lower field reliability than new parts

- Unreliable, as will lower in field reliability as compared to new components

- Environmental risks

Original equipment manufacturers (OEMs) need to understand their entire supply chain.

Cloned components

Cloned components

Cloned components definition per international standard SAE AS6171.

“A reproduction of a part produced by an unauthorized manufacturer without approval or design authority that replicates the authorized manufacturer’s part.”

Cloning of components is an age-old problem and difficult to prove without the original components manufacturers' (OCMs) assistance. In most cases, the OCMs will only assist if components are purchased from franchised distribution.

Cloned components are not ‘black-topped’ components and do not have recycling markings so cannot be detected by visual inspection easily.

Situation & consequences

Cloning is an age-old problem

- Difficult to prove without the OCMs' assistance

- Cloned parts are counterfeit parts

- The OCMs will only assist if purchased from franchised distribution

- Will fail earlier than expected and may operate differently from the official datasheet

- Are not ‘black-topped’ components and do not have recycling markings so cannot be detected by visual inspection easily.

NOTE: Cloning eliminates the large development cost of a part. Cloning can be done in two ways: by reverse engineering or by obtaining design information and/or technical data inappropriately (such as by unauthorized knowledge transfer from a person with access to the original part design).

Original equipment manufacturers (OEMs) are far better off buying from ‘known’ franchised sources as cloned parts are difficult to detect.

Re-manufacture microcircuits

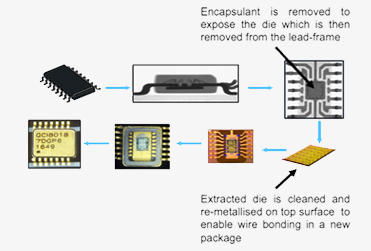

Re-manufactured microcircuits

Re-manufactured microcircuits (ICs) are typically where the die within a component is extracted (using acid and plasma etching), and then the die is re-metalized, repackaged and tested in the desired package to the desired temperature limits.

Can be legitimate – for example, where a higher temperature range component is required – i.e., take a general industry graded component (plastic case part) extract the die and re-manufacture it into a ceramic higher temperature package.

Huge risks involved in the processes result in a decreased mean time before failure (MTBF) of the components.

Components would need to be qualified 100% to the original component manufacturers' (OCMs) original specification.

Long-term reliability is not ensured.

The OCM will legally condemn such action if they are still in business.

Situation & consequences

Sold as a solution for obsolescence.

Can be legitimate

- If the re-manufacturer declares the process and assigns their part number and logo to the re-manufactured component.

Can be illegal and considered counterfeit

- If the re-manufacturer does not use their logo or trademark and passes this off as an original part.

Potentially a safety and reliability risk

- For example, in the CIVIL AVIONICS this would require 100% screening and qualification testing.

Original equipment manufacturers need to know their supply chain, particularly suppliers and OCMs' capability.

Note: the terms ‘counterfeit avoidance’ and ‘anti-counterfeit’ are used interchangeably throughout this overview.

Related documents

Get the briefing paper

IECQ Rules of Procedure

03-7

IECQ 03-7 ed.2.2 (EN)

IECQ Rules of Procedure - Part 7: IECQ Counterfeit Avoidance Programme (IECQ AP-CAP) - Programme Requirements

Counterfeit docs

SAR 3706-1 [AS 5553C] ed.3.1 (EN)

Standard Form SAR - IECQ CAP Assessment Evidence of Compliance Summary and Assessment Reporting Form (SAE AS 5553C)

SAR 3706-2 [AS 6081] ed.2.0 (EN)

Standard Form SAR - IECQ CAP Assessment Evidence of Compliance Summary and Assessment Reporting Form (SAE AS 6081 Rev.A)

SAR 3706-3 [IEC 62668-1] ed.1.1 (EN)

Standard Form SAR - IECQ CAP Assessment Evidence of Compliance Summary and Assessment Reporting Form (IEC 62668-1 Ed.1)

SAR 3706-4 [AS 6496] ed.1.2 (EN)

Standard Form SAR - IECQ CAP Assessment Evidence of Compliance Summary and Assessment Reporting Form (SAE AS 6496)

OD 3707 ed.2.1 (EN)

Operational Document - Assessment Procedures for acceptance of Candidate Counterfeit Avoidance Programme (IECQ CAP) Lead Assessors (LA) and Technical Experts (TE) inthe IECQ AP Scheme

OD 3708 ed.1.1 (EN)

Operational Document - Witness Assessment Checklist for Assessment of IECQ Counterfeit Avoidance Programme (IECQ CAP) Lead Assessors and Technical Experts

TN 009 ed.2.0 (EN)

Technical Notice 009 Ed.2 - IECQ CB Participation Requirements, IECQ Approved Process Scheme - Counterfeit Avoidance Programme (IECQ CAP) [Public Publication]

IECQ 03-1 ed.3.1 (EN)

IECQ Rules of Procedure - Part 1: General Requirements for all IECQ Schemes

OD 015 ed.1.0 (EN)

Operational Document - IECQ On-Line Certificate of Conformity System Guidelines for creating IECQ On-Line Certificates of Conformity

International Standards-Specifications

OD 3702

OD 3702 ed.1.1 (EN)

IECQ Operational Document 3702 - IECQ Counterfeit Avoidance Programme assessment, evidence of compliance, summary and assessment reporting form - Anti-counterfeit traceability audit for any industry segment

IEC 62668-1:2019

Process management for avionics – Counterfeit prevention – Part 1: Avoiding the use of counterfeit, fraudulent and recycled electronic components

IEC 62668-2:2019

IEC 62668-2:2019

Process management for avionics – Counterfeit prevention – Part 2: Managing electronic components from non-franchised sources

AS6496:2014

Fraudulent/Counterfeit Electronic Parts: Avoidance, Detection, Mitigation, and Disposition - Authorized/Franchised Distribution

Franchised distributor plans

AS6174A:2014

Counterfeit Materiel; Assuring Acquisition of Authentic and Conforming Materiel

Counterfeit material: Detection, mitigation and disposition

AS5553D:2022

Counterfeit Electrical, Electronic, and Electromechanical (EEE) Parts; Avoidance, Detection, Mitigation, and Disposition

OEM anti-counterfeit plan

AS6081A:2023

Counterfeit Electrical, Electronic, and Electromechanical (EEE) Parts: Avoidance, Detection, Mitigation, and Disposition - Independent Distribution

Non-franchised distributor plans

Download a copy using the link below

IECQ Protect your investment, reduce your liability

IECQ Counterfeit Avoidance Programme: Leads the way in avoiding counterfeit and recycled electronic components

Available for download: English, French

.

IEC Standards and certification programmes that can help tackle counterfeit in Avionics, Defence and High-Performance (ADHP) industries

Another way to help spot fake merchandise is to address the important issue of counterfeit certificates....

.

IECQ Quality in the electronics industry

Available for download: English

How to get involved

Certification Bodies seeking to provide this IECQ service should submit an application to the IECQ Secretariat using the forms provided.

CB application forms

Form CB Application ed.10.0 (EN)

Standard Form MC-129-Q - IECQ CB Application Form

This form is to be completed by certification bodies seeking acceptance as an IECQ Certification Body (IECQ CB) and once completed is to be reviewed and endorsed by one of the IECQ Member Bodies (IECQ MBs) and then forwarded to the IECQ Secretariat as indicated on the form.

Form CB Extension of Scope ed.11.0 (EN)

Standard Form MC-130-Q - IECQ CB Application for Extension of Scope

This application & capability declaration form is to be completed by accepted IECQ Certification Bodies (IECQ CBs) when seeking to extend their scope of IECQ acceptance to other IECQ Services and new or revised Standards / Specifications. The completed form is then forwarded to the IECQ Secretariat as indicated on the form.

Join IECQ WG 06

Get involved in the counterfeit avoidance working group by Contacting us

WG06 is a working group of the IECQ Management Committee tasked to develop and maintain rules and operational documents to ensure the global harmonised application and effective operation of IECQ Counterfeit Avoidance - Approved Process Certification under the IECQ Approved Process Scheme. While the IECQ Counterfeit Avoidance Programme shall meet the needs of the Aerospace, Defense, and High Performance (ADHP) industry, the Programme shall be developed such that it allows for industries other than the ADHP industries, noting that different industries may require differing criteria.